In today’s packaging-intensive world, choosing the right film supplier is critical: the film you select affects barrier performance, print quality, cost-efficiency, sustainability and brand appeal. When it comes to metallized polyester films, which combine a polymer base with a thin metal coating (typically aluminium) to achieve both barrier and aesthetic benefits, the stakes are high. As a leading provider of packaging films and related solutions, Kanodia India brings together technology, scale and service to deliver high-performance metallized film solutions.

Why Metallized Polyester Films Matter

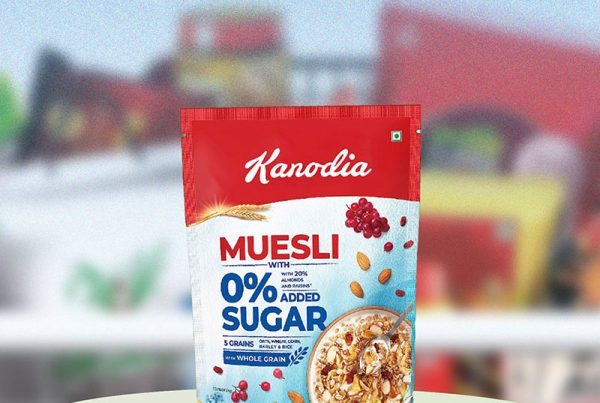

Metallized polyester films offer a unique combination of attributes: exceptional barrier properties (against moisture, oxygen and light), dimensional stability, excellent printability and a premium metallic finish. They’re used widely in snack pouches, coffee bags, capsule packs, labels, decorative laminates and more. Selecting a capable supplier for metallized polyester film manufacturers means choosing a partner who understands both the technical demands and business imperatives of packaging.

Key Qualities to Evaluate

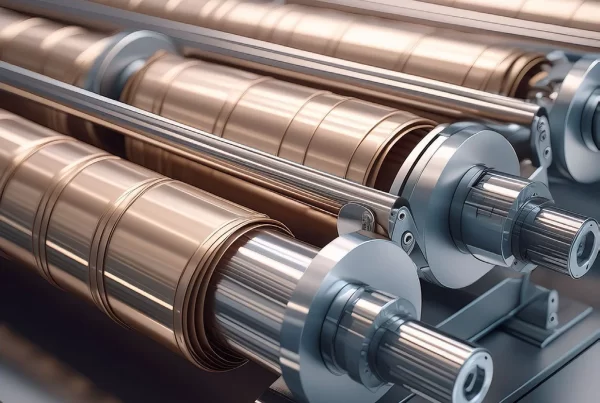

- Advanced Manufacturing Technology & Capacity

A top-tier film manufacturer must have modern production lines, wide vacuum-metallization ovens, sophisticated coating/plating systems and strict quality control. For example, Kanodia India highlights metallization lines up to 3.25 m wide for substrates such as BOPET, BOPP and CPP films. High capacity ensures consistent supply, faster lead times and the ability to scale with your business.

- Material & Structure Flexibility

Packaging demands vary: you might need thin films for snack wrappers, medium-thickness films for freeze-pack or heavy-duty film for industrial use. A reliable manufacturer offers a range of thicknesses, substrates and multi-layer structures. Kanodia India, for instance, offers metallized and window-metallized films, custom structures, and collaborates closely with customers to tailor films to substrate and barrier requirements.

- Barrier Performance & Print-Readiness

Barrier attributes matter for product shelf-life and brand integrity. Equally, the film must support high-quality printing and lamination. When you partner with Kanodia India, their advanced lines and film technology deliver high barrier performance and excellent surface for printing or lamination.

- Quality Assurance, Certifications & Consistency

Material consistency, uniform metallization, minimal defects and accurate thickness control are what separate leaders from the rest. Kanodia India emphasises strict quality processes, using German equipment (Windmöller & Hölscher, Kuhne) and highlighting precision in both film and metallized coating. Reliable quality means fewer rejects, smoother production and better brand outcomes.

- Sustainability & Future-Readiness

Today’s packaging world demands environmentally aware solutions less material, recyclable structures, reduced energy use. The right film supplier supports these needs. Kanodia India offers recyclable multi-layer films, window-metallized options and reduction in metal usage while maintaining quality. This is especially important for brands that care about their ESG credentials.

- Service, Support & Lead Times

Even the best film is only as good as the service behind it. A manufacturer must offer excellent customer support, rapid turnaround, technical consultation and supply chain reliability. Kanodia India’s website emphasises quick delivery schedules and strong service commitment.

How Kanodia India Delivers These Qualities

Kanodia India’s production infrastructure, technology investment and service orientation make them a go-to for brands requiring metallized polyester and related films. They support custom structures, large capacities, metallization of multiple substrates, focus on barrier and aesthetic performance, and back it up with service and quality standards. With mature capabilities across flexible packaging films, the company offers integrated solutions making them not just a film supplier but a strategic packaging partner.

What This Means for Your Brand

Partnering with a film manufacturer that ticks all the quality boxes means your brand benefits from:

- Superior shelf presence due to metallic finish and print clarity

- Reduced film waste, fewer production stoppages and higher throughput

- Enhanced product protection (longer shelf life, fewer customer complaints)

- Lower total cost over lifecycle (less rework, fewer rejects, more reliable supply)

- Improved sustainability credentials and better compliance with brand responsibility goals

Final Thoughts

If your packaging strategy depends on high-barrier, visually appealing, and technically reliable films, choosing the right manufacturer is crucial. As one of the trusted names in the field, Kanodia India stands out for its advanced manufacturing, versatile film structures, commitment to quality, service excellence and sustainability focus. In the category of metallized polyester film manufacturers, selecting a partner who delivers on all fronts gives your brand a competitive edge. Choose smart, partner well, and your packaging will perform as powerfully as your product.

FAQs

What should I check before selecting a metallized polyester film supplier?

Look at manufacturing technology (metallization width, machinery brand), range of film structures, barrier performance, customer service, lead times and sustainability credentials.

How do metallized polyester films improve packaging performance?

They offer high barrier protection against moisture, oxygen and light, maintain print clarity and enhance visual appeal with metallic finish helping extend shelf-life and boost brand image.

Can Kanodia India customize film structures for specific applications?

Yes. Kanodia India offers tailored film solutions choosing substrate, thickness, barrier performance, metallization and additives to align with the specific needs of food, pharma, FMCG and industrial packaging.

Why is sustainability increasingly important for film selection?

Brands are under growing pressure to reduce material use, support recyclability, cut carbon footprint and design for disposal. A supplier with recyclable structures and eco-design helps meet those goals.

How does lead time and capacity affect film sourcing?

High manufacturing capacity and efficient lead times reduce risk of stock-outs, production delays and rush-charges. A supplier like Kanodia India emphasises scale, quick delivery and supply reliability.