In today’s fast-moving consumer goods market, packaging is more than a means to protect products it plays a central role in branding, shelf life, cost optimization, and supply chain efficiency. Working with a top packaging films provider in India brings strategic advantages that ripple across logistics, manufacturing, and end-user satisfaction. Here’s how a partner like Kanodia Technoplast helps businesses tighten up their supply chains and deliver better value.

Understanding the Role of Packaging Films in the Supply Chain

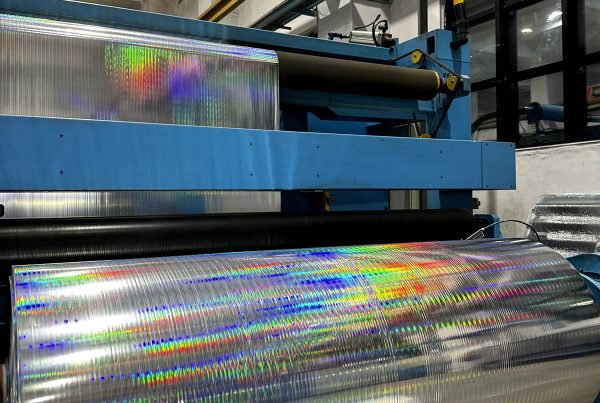

Packaging films whether CPP, BOPP, metallized, or holographic serve multiple functions: barrier protection, visual appeal, seal integrity, weight control, and safety. Poor choices can lead to product damage, returns, delays, and increased costs. The right film helps maintain product quality during transit, reduces waste, and ensures that downstream processes (filling, packaging, transport) run without hiccups.

Being a Reliable Global Packaging Film Provider India Brings Key Benefits

Choosing a supplier with global quality standards ensures that your packaging films are consistent in performance and compliance. Here’s what that means in practice:

- Consistent Quality & Certifications: Standardized line speeds, superior barrier properties, and compliance with food safety and environmental norms reduce inspection failures and regulatory risk.

- High Capacity & Faster Turnarounds: Strong production capacity allows for shorter lead times. Kanodia’s manufacturing setup features high-capacity production (over 18,000 MT annually), meaning you can scale without supply delays.

- Technology & Innovation: Using advanced equipment (German origin lines, wide metallizing units, precision printing) ensures fewer defects, tighter tolerances, and flexible film options. Converts and brands get packaging that works smoothly in converting lines without downtime.

- Sustainability Built In: Eco-friendly films, recyclable multi-layer structures, material reduction, and efficient film designs not only meet consumer and regulatory expectations but often reduce material costs and disposal overhead.

Specific Ways Kanodia Technoplast Streamlines Supply Chains

Kanodia Technoplast brings several practical advantages that directly optimize supply chain operations:

- Customized Film Structures

They offer specialized films high-barrier films, metallized, vacuum-metallized, holographic, CPP, BOPP—tailored to product requirements like moisture, gas barrier, or aesthetics. Using the right film minimizes spoilage and returns. - Low Thickness, High Performance Films

With innovations like thin 15-micron CPP films (under their KANCAST-PP portfolio), products get protection with less raw material. That means lighter shipments, less material waste, and lower transportation costs. - Reliable Supply & Larger Capacity

With large production capacities and robust infrastructure, Kanodia helps avoid stockouts and enables reliable planning. Brands can forecast demand better and inventory less in high lead time zones. - Integrated Printing & Cylinder Supply

Having printing cylinder services (rotogravure cylinders) in-house improves turnaround. There’s less back-and-forth, fewer defects, and better alignment between film and printing. This reduces lead time and ensures visual and quality consistency. - Sustainability & Regulatory Support

Films designed for recyclability, safety, and lower environmental footprint reduce regulatory risk and possible disruption in exports. Also, being ISO 9001, ISO 22000 etc. certified helps with quality audits and customer trust.

Impact Across the Supply Chain

Let’s map out how these strengths manifest at each stage of a typical supply chain:

| Stage | How Kanodia’s Services Help |

| Procurement | Consistent quality, certifications, bulk film supply reduce variability and streamline ordering. |

| Manufacturing / Conversion | Films that run well at high speeds, precise printing, fewer rejects. Saves downtime. |

| Packing & Filling | Films designed for seal strength, barrier protection keep product intact during packing & transport. |

| Storage & Handling | Durable films resist moisture, tearing. Less damage in transit or warehouses. |

| Transport & Distribution | Thinner films with same performance = lighter loads, lower freight costs. |

| Retail Display | Higher visual appeal and durability reduce damage; reclosable options improve customer satisfaction. |

Cost Savings & Efficiency Gains

Working with a capable provider like Kanodia Technoplast yields several measurable benefits:

- Reduced Material Costs: Using thinner, multi-layer films that achieve required performance.

- Lower Transportation & Handling Costs: As packaging becomes lighter or more compact.

- Less Waste & Damages: Better barrier, better seal, fewer spoils/damages in transit or storage.

- Improved Lead Times & Inventory Efficiency: High manufacturing capacity reduces order delays; you can keep optimised inventory.

Choosing the Right Film Provider: What to Look For

When selecting a packaging film partner, ensure these criteria:

- Technical expertise in film formulation & converting line compatibility

- Strong infrastructure and large production capacity

- Ability to customize films as per product, barrier needs, printing, sealing requirements

- Eco-friendly practices, sustainability, regulatory compliance

- Reliable quality & consistency, minimal defects

- Responsive supply chain: on-time delivery, ability to scale when required

Final Thoughts

If your business depends on packaging for food, pharma, hygiene, consumer goods, or industrial products optimizing the packaging film supply chain yields benefits in cost, efficiency, sustainability, and customer satisfaction. Kanodia Technoplast offers a combination of technological strength, consistent quality, sustainability, and customization that makes it a solid partner for streamlining packaging operations.

By leveraging their capabilities in high-barrier films, vacuum metallization, holography, thin CPP films, and strong global compliance, brands can reduce waste, improve turnaround, cut costs, and build supply chains that are more resilient and responsive.

With the right packaging film provider, your supply chain becomes not just a back-end cost center but a competitive advantage helping your brand deliver reliably, sustainably, and profitably.

FAQs

What products does Kanodia Technoplast manufacture?

Kanodia Technoplast produces high-barrier packaging films, CPP and BOPP films, metallized films, and holographic films for diverse industries.

How do Kanodia Technoplast’s films improve supply chain efficiency?

Their lightweight, high-performance films reduce transportation costs, minimize product damage, and ensure smoother high-speed packing.

Are Kanodia Technoplast’s packaging films eco-friendly?

Yes. They develop recyclable and sustainable film structures to help brands meet environmental and regulatory standards.

Can Kanodia Technoplast customize films for specific product needs?

Absolutely. They tailor barrier properties, thickness, and print compatibility to match each client’s product and market requirements.

Does Kanodia Technoplast serve global markets?

Yes. As a trusted Global Packaging Film Provider India, Kanodia Technoplast exports to multiple international markets while meeting global quality certifications.